The Soil Mixing technique is represented by the combined action of modern soil consolidation techniques through injections of mostly cement-based admixtures, and soil mobilization/mixing performed through the use of rotating tools.

The result of this action is the creation of columnar elements consisting of “improved” soil in its main geotechnical features.

The soil consolidation through Soil Mixing technique is applicable in a wide range of natural soils (between clay and gravel) and is characterized, in particular, by a very low removal of material (Spoil) with minimal interactions with the surrounding volume.

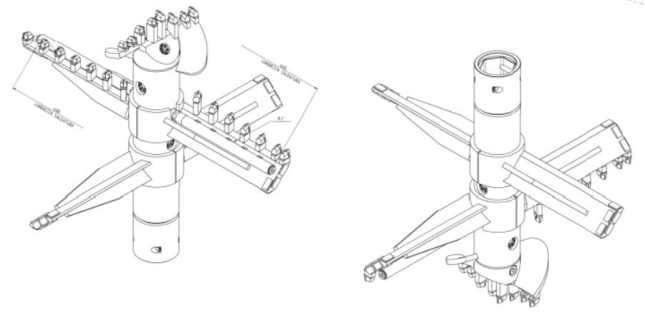

The creation, by means of Soil Mixing, of columnar elements, with a well-defined geometry, generally consists in the insertion in the ground of rotating tools on which augers and / or mixing blades are installed; there are also nozzles, from which comes out the consolidating admixture, that will be fed through hollow drilling rods on which the aforementioned tools are mounted.

As already mentioned, the consolidating admixtures generally consist of suspensions of water and cement, with possible additives such as bentonite. The proportions between the various elements constituting the injected admixture vary according to the geotechnical characteristics of the treated soil and the final result required in the design stage once the treatment with the Soil Mixing technique has been carried out.

SOIL MIXING:

HOW IT WORKS AND OPERATIVE PHASES

The Soil Mixing technique involves the following main operative phases:

1. SOIL MIXING - DRILLING

In relation to the designed treatment depth, which will be reached through the use of suitably set up drilling rigs equipped with high rotation torque and specific drill strings consisting of rods + rotating tools, a hole is made up to the predefined depth.

The drilling fluid generally consists of waterbut, in some cases, depending on the purpose of the consolidation treatment or the characteristics of the natural soil,

the same consolidating admixture can be used.

2. SOIL MIXING - INJECTION

Once the target depth has been reached, the consolidating admixture will be pumped at a pre-defined pressure and flow rate by means of the same pump employed for the drilling fluid, according to the design requirements.

Generally, injection pressures higher than 250 Bar are NOT expected; with JSM (Jet Soil Mixing) technique (Foreseen injection pressure: 250 Bar) are combined the mechanical action of the rotating tool with the mixing action induced by the high-pressure injection carried out through the nozzles.

Generally speaking, we can consider injection pressures of 150 ÷ 200 Bar.

Once the project injection pressure has been reached, the drill string and therefore the "rotating mixing tool" will be made to rotate at a predefined speed and, at the same time, extracted from the hole, creating a columnar element of consolidated soil having a perfectly defined geometry; constant over time and space.

SOIL CONSOLIDATION THROUGH SOIL MIXING: APPLICATIONS

The "SOIL MIXING" technique is mainly applied in the following fields:

SOIL CONSOLIDATION THROUGH SOIL MIXING: EQUIPMENT

METAX produces and designs the following equipment for Soil Mixing injections:

HORIZONTAL SILOS (PHS) | VERTICAL SILOS (PVS)

HORIZONTAL SILOS (PHS) | VERTICAL SILOS (PVS)

Storage unit for powder components: with different capacities according to the specific needs of the Customer.

MIXING PLANT (MIXP)

MIXING PLANT (MIXP)

Mixing unit type with different hourly capacities according to the specific needs of the job-site.

MIXING & INJECTION PLANTS (MIP)

MIXING & INJECTION PLANTS (MIP)

INJECTION PUMPS (IP - MP)

INJECTION PUMPS (IP - MP)

Separate pumping units, with high and very high pressure injection pumps type IP140H, IP100V and Triplex Motorpumps MP4 | MP5.