Jet-grouting is a modern, fast and effective method for soil consolidation and creation of special foundations in natural soils and sometimes in soft rocks. The natural soil consolidation consists in the modification and improvement of its mechanical features with a contemporaneous decreasing of the natural permeability.

A jet-stream of cement-based admixture, which flows through the nozzles placed at the end of a rotating rod which is gradually retrieved, disaggregates ("Cuts") the natural soil structure allowing the soil itself to be mixed with the injection fluid ("Stabilizer"). In this way the jet determitates the creation of columns and bulkheads of "soilcrete" by treating the ground in situ.

The objective of jet grouting is to obtain soil improvement in a controlled manner, both from a physical point of view, because it delimits the treatment radius, and from a qualitative point of view, because predefined characteristics of the treated soil are obtained, objectives that are difficult to achieve with conventional injection techniques. We can argue that jet grouting has no disadvantages, except for the need to perform test fields in order to verify the accuracy of the injection parameters and the effectiveness of the treatment.

Thanks to Jet-Grouting it is possible to treat a wide range of soils including gravels and clays. With Jet-Grouting it is possible to foresee the quantity of "stabilizer" necessary to obtain the required result, before starting the works on site; in this context, the final result, in terms of resistance and permeability, can be foreseen in the design stage as well as costing (jet grouting job-site cost).

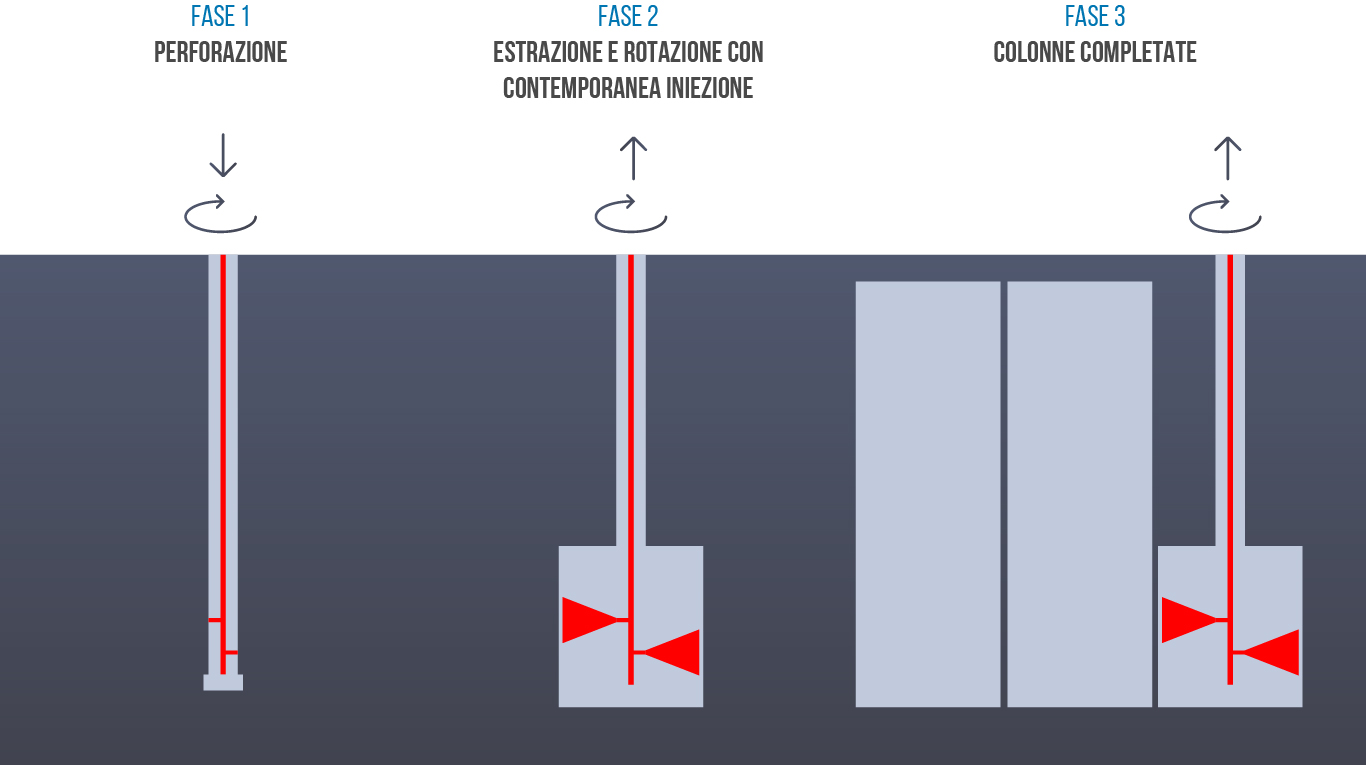

JET GROUTING OPERATIVE PHASES

1. DRILLING

In relation to the designed treatment depth, through the employment of common drill rigs and by mean of specific drill strings as first step is performed an hole up to the previously designed depth (1). Common drilling fluid is water but, in some cases, are used grout or additivated water based admixtures (i.e. bentonite).

Depending on the type of soil to be treated, three different methods are used for the execution of jet grouting. The methods differ in the position of the nozzles along the nozzle holder monitor but, above all, in the type and number of employed fluids.

2. INJECTION

Once reached the designed depth, the grout admixture (Previously prepared by mean of specifc Mixing Units) is pumped at high pressure from the triplex pump, through the transferring line up to the bottom of the drill string where are located the injection nozzles.

During the injection phase (2-3-4), the drill string is extracted at a predefined speed (Usually sec./4 cm step or sec./m) and simultaneously rotated; this combinated action creates pseudo-cylindrical elements (J-G Columns) of improved soil.

JET GROUTING: MAIN APPLICATIONS

The jet grouting technique is applied in all fields of geotechnics which include both underground and open-air excavations.

It is mainly used as:

JET GROUTING EQUIPMENTS

METAX, the geotechnical division of CIMA S.p.A., designs and produces its own production range for jet grouting application.

HIGH PRESSURE MOTORPUMPS

High pressure triplex pumps driven by diesel or electric engines.

MIXING/INJECTION COMPACT SYSTEM FOR JET GROUTING

Jet grouting plant built inside a single container with an high-pressure triplex pump and a mixing plant, particularly suitable for downtown job-sites or for confined areas.

These systems can be powered by electric or diesel engines.

Would you like more information

on the technique or on jet grouting machines?

CONTACT US

METAX | Geotechnical, Drilling and Oilfield Division of Cima SpA, since 1987 is specialized in the construction and design of high-pressure triplex motor pumps, mud pumps, mixing and injection plants, mixing plants and storage equipment for cement-based admixtures for the following applications: soil consolidation by means of jet grouting, tunneling & backfilling, drilling and guided drilling.