The application of tunneling, in a general, and of backfilling in particular, are used in the construction of tunnels (hydraulic, railway, road and other)

When we talk about tunneling, we refer to the different construction techniques used for the construction of tunnels that can be excavated "traditionally", for example with the "drill and blast" and "cut and cover" techniques and according to the "mechanized excavation" through the use of TBM (Tunnel Boring Machine).

METAX equipment are mainly used both for the consolidation of the soil crossed by the tunnels, and for the annular gap filling (backfilling) behind the tunnel lining segments.

Consolidations:

Depending on the degree of water presence, the aforementioned techniques will be adopted, with important variations on the composition of the injection admixtures.

The main objective of the consolidation techniques described above is to modify the physical and mechanical conditions of natural soils, in order to allow them to be excavated safely and economically.

Operational phases of the techniques used in Tunneling

1. Sub-horizontal jet-grouting and / or sub-vertical jet-grouting

2.Sub-horizontal and / or sub-vertical Injectoins

In tunneling, when we talk about "mechanized excavation" carried out through the use of TBM (Tunnel Boring Machine), it is necessary to open a specific chapter relating to the backfilling application.

Backfilling

Backfilling technique, for tunnel construction, is closely linked to "mechanized excavation".

For "mechanized excavation”, and therefore for backfilling, special machines (TBMs) are used that are

capable of:

Once the tunnel lining has been laid, it is necessary to fill in the annular space that remains “free/empty” between the excavation profile in the ground and the external surface of the reinforced concrete lining.

The filling of the “free” annular volume, eliminates the possible settling of the ground surrounding the

excavation which could induce differential subsidence of both the tunnel and any existing superficial

structures. It also significantly increases the degree of waterproofing of the tunnel itself.

In general, two-component mixtures are produced and injected on the back of the lining segments:

A": admixture of water, bentonite and cement, improved with retarding additives, to ensure long "workability" times of up to about 72 hours and therefore allow it to be pumped for a long time and long distances.

accelerating additive, which is transferred to the TBM as the Component "A" and then injected, together with it, on the back of the segments, in order to obtain a rapid hardening and setting action of the injected "bi- component ” final admixture.

Machines for Tunneling and Backfilling

MIXING PLANTS

For "traditional" techniques

The mixing plants (usually powered with electric motors) manufactured by METAX, can produce

consolidating admixtures that will be injected into the ground, according to the techniques of jet grouting

and / or classic injections with or without "TAM pipes". They are able to work both manually and

automatically, with an hourly production capacity (5 ÷ 50 and over m3 / hour) defined considering cement-

based admixtures with W / C ratio = 1.

The mixing plants can provide particular and more sophisticated technical measures, in the event that a

greater number of components of the admixture itself is required, with the need to have different recipes.

for "Backfilling"

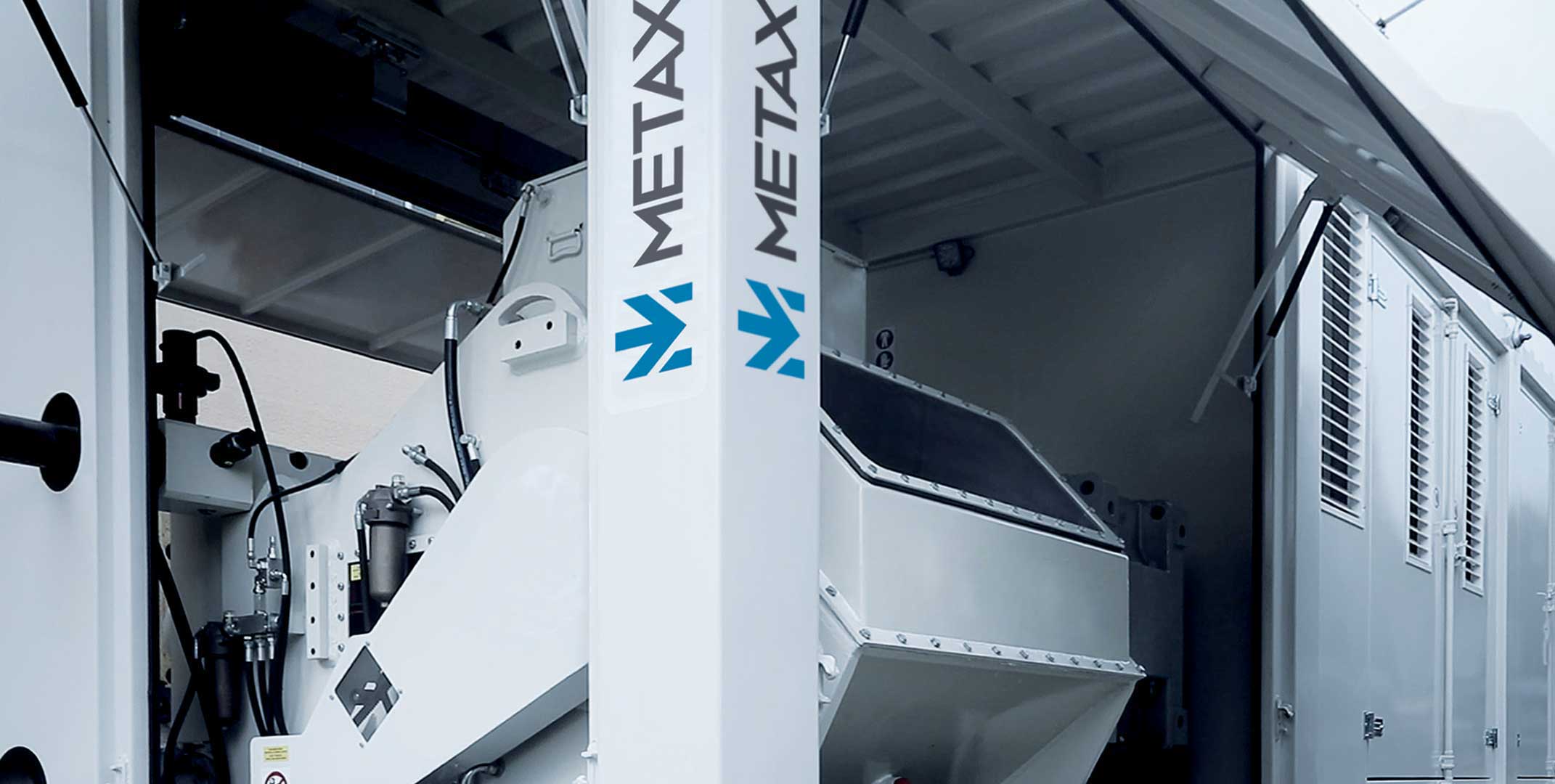

METAX designs and produces mixing plants for backfilling of adequate hourly capacity according to the specific needs of the construction site, which are mostly set up inside 20 '(feet) containers. Their hourly production capacity (10 ÷ 50 and over m3 / hour) is generically defined considering cement- based admixtures with ratio W / C = 1; for the production of “bi-component” admixtures, this hourly productivity will decrease as a function of the number and quantity of the ingredients making up the recipes of the “bi-component” admixtures themselves and of the intermediate mixing times.

INJECTION PUMPS

High Pressure Triplex Pumps

Triplex pumps can be powered by both diesel and electric motors.

The high pressure motor-pumps produced by METAX have the following main features:

"Low" pressure injection and transferring pumps

For traditional injections and / or for the long-distance transfer of bi-component admixtures

METAX designs and manufactures a wide range of single and double piston pumps (injection pumps),

generally electrically powered.

HOLDING TANKS (Agitators) FOR ADMIXTURES AND / OR LIQUID ADDITIVES

To keep the produced admixtures and liquid additives, in suspension, in optimal conditions, METAX produces a wide range of holding tanks with a range of capacities from 0.5 m3 to 20 m3.

POWDER AND LIQUID STORAGE SILOS

The line of products for tunneling and backfilling is completed by a large series of silos for powders storage (cement, bentonite, fly-ash, etc ...) and liquids ("bentonite liquor", accelerator, retarder, etc .. .).

In particular:

Would you like more information on tunnelling

and backfilling technology or machines?

CONTACT US

METAX | Geotechnical, Drilling and Oilfield Division of Cima SpA, since 1987 is specialized in the construction and design of high-pressure triplex motor pumps, mud pumps, mixing and injection plants, mixing plants and storage equipment for cement-based admixtures for the following applications: soil consolidation by means of jet grouting, tunneling & backfilling, drilling and guided drilling.