The term workover means a large serie of interventions, performed on oil wells (Oil & Gas), which involve the use of particularly invasive techniques including, for example, the one called coiled tubing.

Workover interventions are often performed in order to extend the life of an oil well and are characterized by very expensive processes of replacing parts of the well or cleaning the well itself.

Sometimes workover works are carried out, even immediately after having carried out the completion phase of the well itself, having not obtained the productivity results defined in designing phase.

The first phase of workover on oil wells consists in the interruption of the production of the well in question through the action defined as killing at the end of which a well passes from "supplying productive well" to "non-supplying productive well".

WORKOVER ON OIL WELLS: APPLICATIONS

COIL TUBING

Coil Tubing consists in the insertion, inside an existing well, of a particularly elastic, resistant and small diameter pipe, through which various operations will be carried out according to the specific problems / situations that characterize the well under maintenance. With coil tubing, mainly, the following activities can be performed:

WATER INJECTION

Water Injection consists in the reintroduction of the appropriately treated "mother" water into the deposit by pumping it, under pressure, in order to stimulate and wash the reservoir and thus extend its productive life. This application is mainly performed on "mature wells".

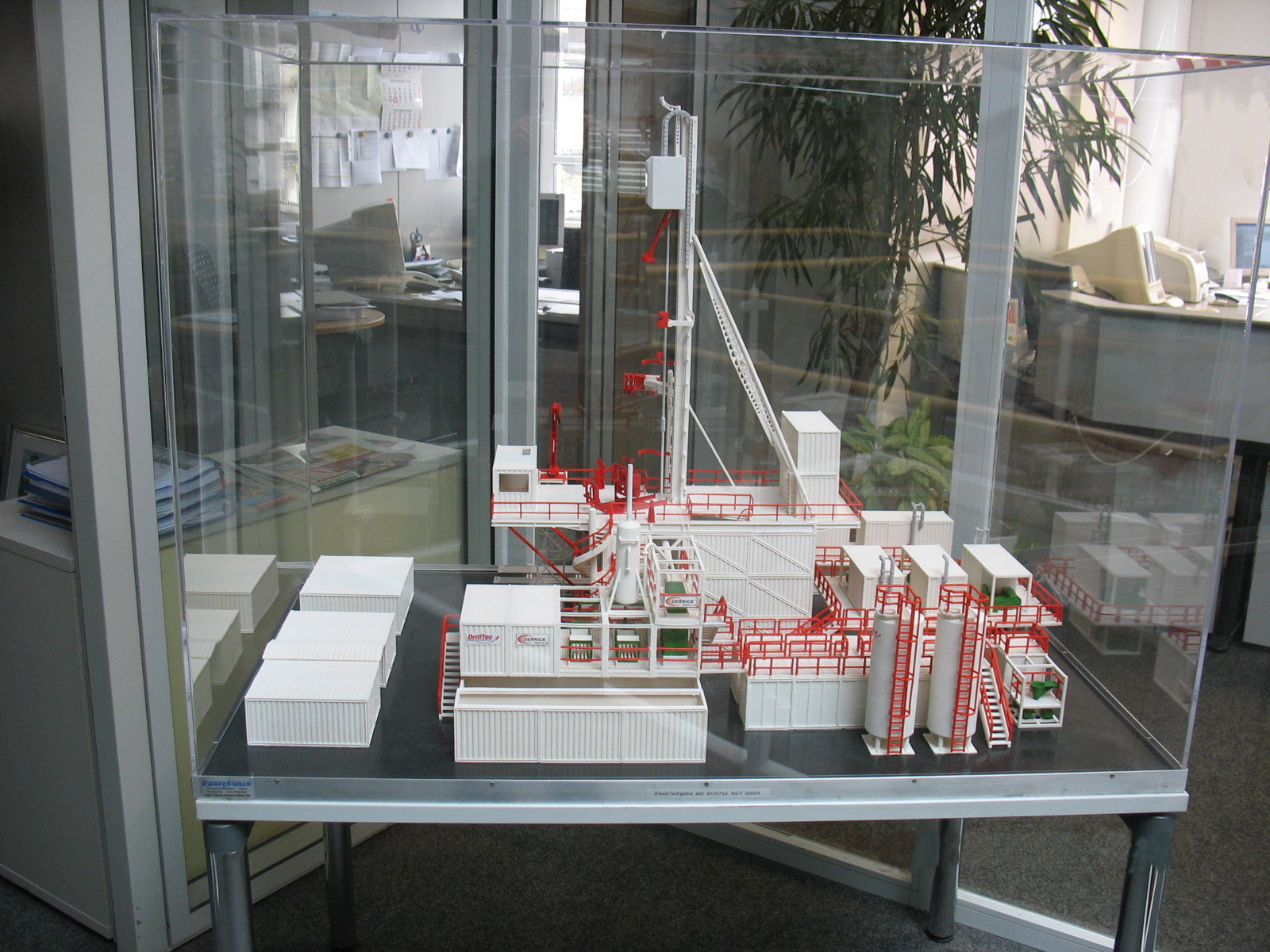

WORKOVER: EQUIPMENT

On the basis of the above, it is evident that, in order to perform workover works, it is often necessary to pump fluids of various characteristics and with various purposes.

Regarding equipment suitable for workover on oil wells, METAX includes in its product range:

MP4 | MP5 | MP7

MIXP

Suitable for the preparation of drilling muds and cement mixtures for cementing wells.

For the following applications: